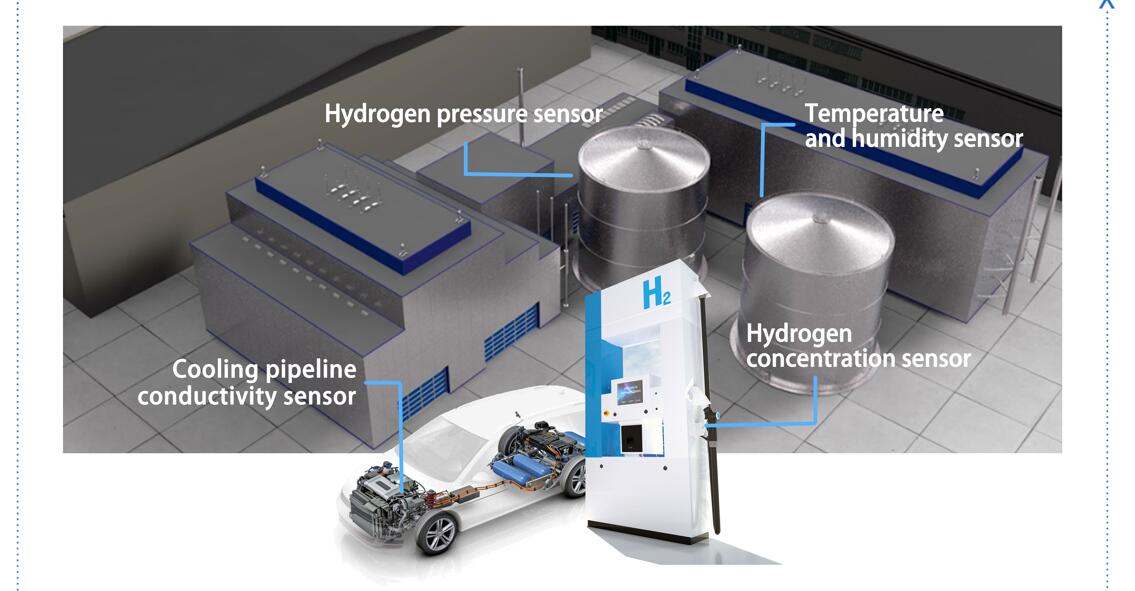

Hydrogen energy monitoring

Program Overview

As the "blood" coolant of the fuel cell cooling system, its "trace element" content is crucial to the normal operation of the system. During the circulation process of the coolant, the "impurities" will continue to increase, resulting in a continuous increase in its conductivity, a decrease in the resistance value, and a decrease in the insulation performance of the system. In order to ensure safety, the electrical insulation performance of the fuel cell cooling system, especially the high voltage electrical insulation performance, is very important, which requires reducing the electrical conductivity of the fuel cell cooling fluid. Therefore, the coolant is required to have high heat dissipation, low corrosion rate, high seal material compatibility and ultra-low conductivity. The industry usually requires the conductivity of the coolant to be less than 5μS/cm, which requires real-time detection of the conductivity of the fuel cell engine coolant.

Scheme Architecture

Program Value

● It improves the service life and safety of fuel cell engine

● Real-time monitoring to achieve accurate measurement, which is beneficial to deal with unexpected problems and special situations

● Reduce the dependency and time limit of manual maintenance

Related Products

Project Cases

Vehicled-board conductivity sensor

The vehicle-mounted conductivity sensor of this project is specially customized for the fuel cell cooling system. At present, most domestic fuel cell engine system integratorssuch as Beijing Yihuatong, Shanghai Remodeling, State Power Investment Corporati